Painting Equipment

Other Categories

- Assembly Line

- Custom Spreader Bars

- Dolly Hydraulic Lift

- Glass Cutting Tables

- Glass Handling Equipment

- Glass Harp Racks

- IG Equipment

- Lifting Equipment

- Material Handling Equipment

- Material Handling Tables

- New Equipment

- Painting Equipment

- Pneumatic Tilt Tables

- Racks & Carts

- Rubber Wheeled Cart

- Storage Equipment

- Stretch Wrapping Equipment

- Table and Air Tables

- Transfer and Power Conveyor Equipment

- Window and door Production Line Equipment

-

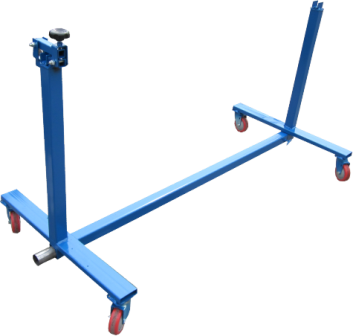

K-70TEL

Door Paint Dolly Expandable

-

K-70RS

Door Stain & Paint Dolly with Manual Rotation and Brake

-

K-70DD

Dry Dolly & Painting Dolly

-

K-70PD

Dry Dolly & Painting Dolly

-

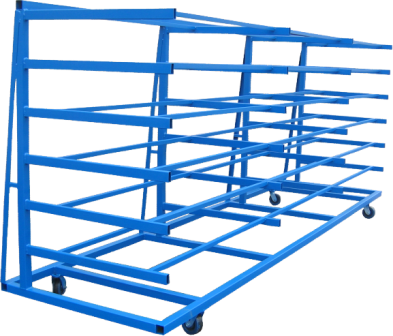

K-70V

Dry Rack (Glass Painting)

-

K-70GDD

Glass Curing Paint Dolly

-

K-70RRP

Manual Rotate Stand with Expandable

-

K-70TED

Paint Curing Station

Painting Equipment

Kear Fabrication INC.'s painting equipment promotes highly durable and practical painting and curing equipment used for various industrial and manufacturing applications. This includes improving efficiency, consistency, and quality in paint application and drying.

Moveable Painting Equipment Provide Accuracy

In industrial painting, painting tables and movable equipment is a primary and must-have solution. It is required to provide an organized surface that is stable for the painting process, especially from small to medium-sized parts. Painting equipment facilitates ergonomic working conditions, reducing strain and improving efficiency. Often, painting tables have grid tops or downdraft capabilities, which effectively manage overspray and help create a cleaner working environment. Using accurate equipment dedicated to the project can make assembly and finishing work easier within settings. It also allows painters to access all sides of the area with ease to maintain uniformity.

Simplify Material Manageability With Equipment

Dollies and carts have become essential pieces of equipment for moving parts from one part of the painting operation to another, ultimately, from surface to surface. Their function is to improve the flow of work and reduce physical handling, thus increasing productive efficiency. Many such dollies now come with rotating platforms for added flexibility and ease of use. They transport parts to and from preparation, to painting, and then curing. They can also be used to move painted components to their final storage or assembly area. Most importantly, they can be used as temporary holding platforms for rotation or repositioning of painted parts, the process rendering easy coverage of all areas.

Providing High-Quality Drying Solutions

Window and door curing racks and systems specifically provide a controlled environment for drying and curing painted windows and doors. These tools are crucial to drying painted window frames and sashes, as well as curing painted door panels and complete door assemblies. The design of these racks is very important because they are constructed to keep windows and doors apart while keeping them from sticking or being scratched while the paint cures, maintaining quality and integrity in the finished products. You can request us for a quote or customize your own quote list to let us know what you want to shop from us!

Key Considerations for Equipment Selection

- The most important is material compatibility; therefore, the equipment should be compatible with all types of paints and coatings for maximum efficiency and prevention of damage.

- The second major consideration is size and capacity; the equipment dimensions and load capacity must match the dimensions and weight of the painted parts to ensure safe and effective operation.

- Adequate ventilation for all processes is a must, especially on downdraft tables and curing systems, which should be properly ventilated to remove fume buildup and ensure safety.

- Another critical consideration is durability and construction; therefore, industrial painting equipment must be sturdy and durable to bear heavy use in hostile environments, thus ensuring a good serviceable life and reliability through proper performance.