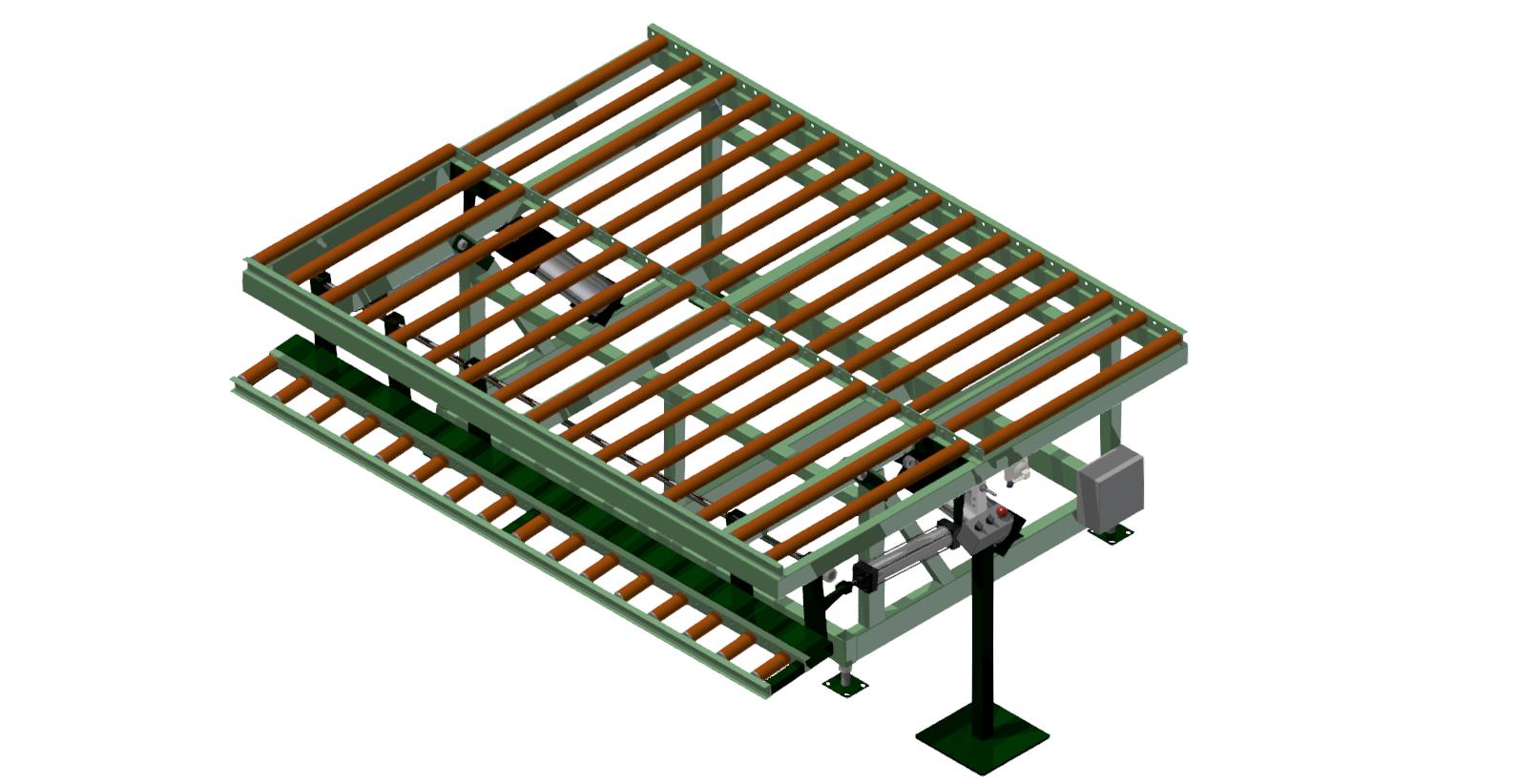

The Air Float Table is a customizable solution designed to improve glass handling, seaming, sanding, and cutting. Built for efficiency and flexibility, it suits glass fabricators looking to speed up workflow and reduce manual strain. You can adjust its dimensions to fit various glass sizes and shop layouts, making it adaptable to different production needs.

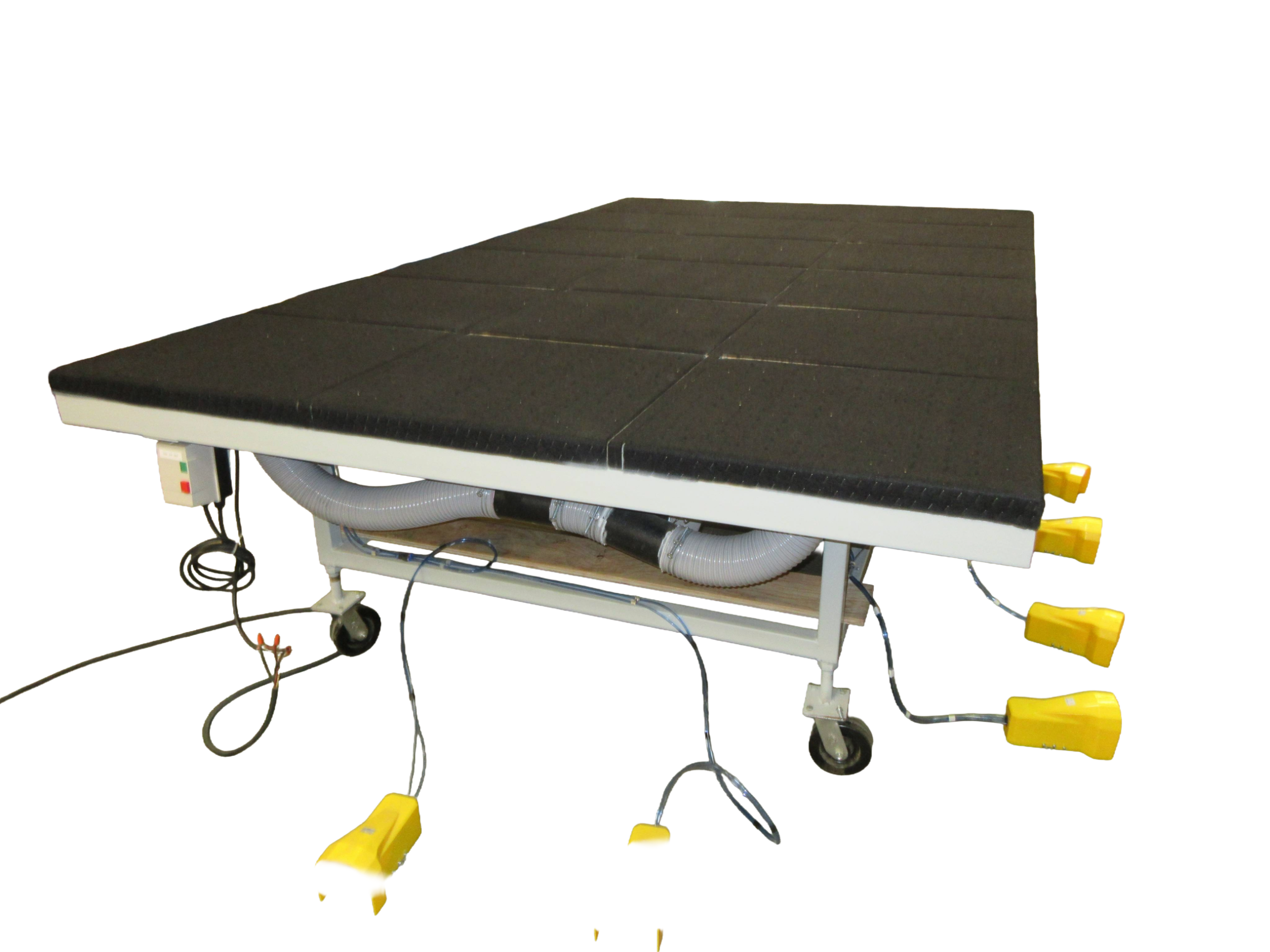

A carpeted tabletop protects glass surfaces from scratches during movement, with optional upgrades available for added durability. At the core is a powerful air blower system that creates smooth, frictionless movement across the table. Choose between 1HP for 3–5mm glass, 3HP for 5–8mm, or 5HP for 8–12mm, depending on the glass thickness.

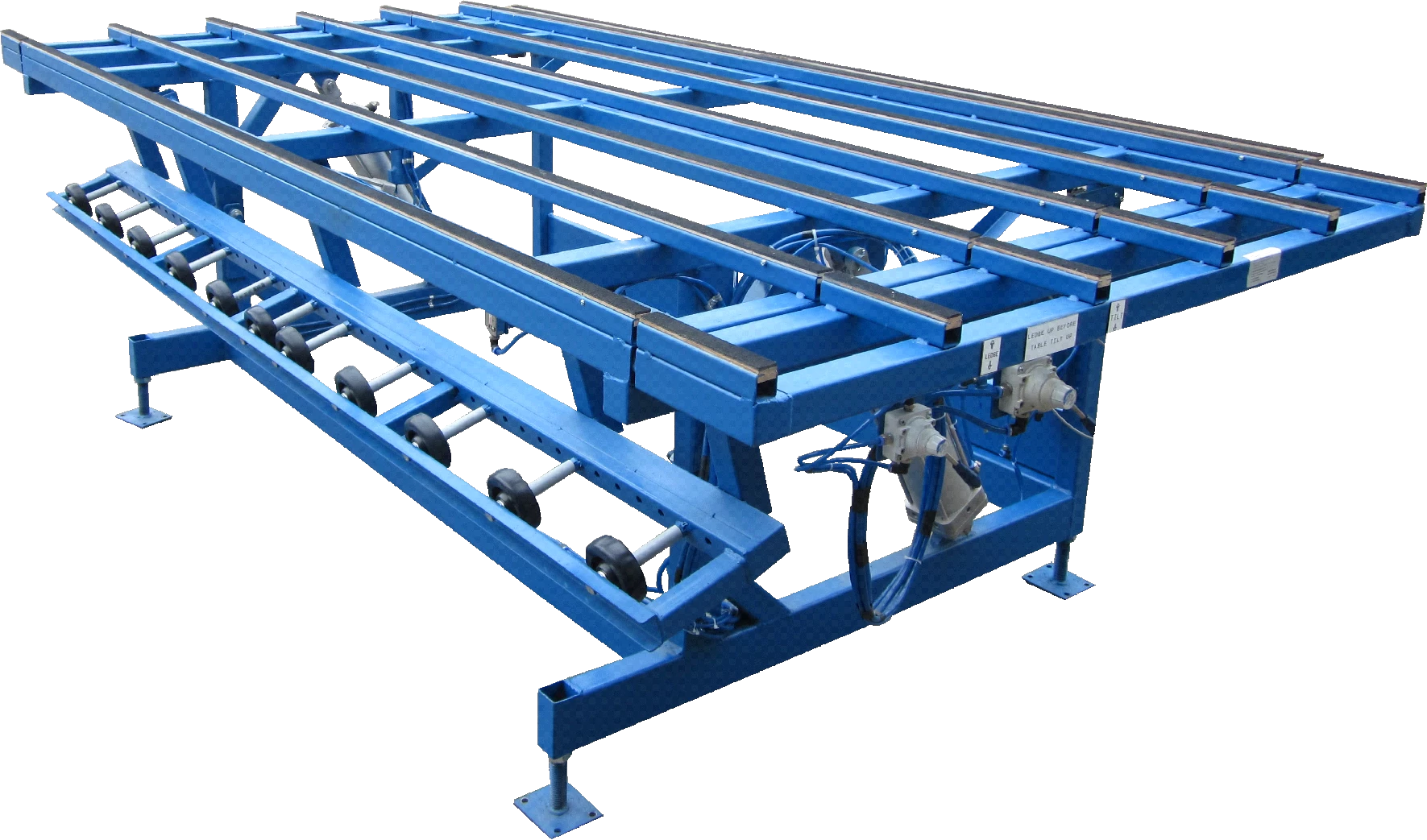

The table also offers several performance-enhancing features. Breaker bars allow for accurate scoring and cutting. Optional casters provide mobility, so you can move the table as needed. For seamless integration into your production line, you can add a track system to connect with other workstations.

Whether handling standard sheets or jumbo glass, the Air Float Table gives you the control and efficiency to keep up with high production demands. Its smooth operation reduces handling time and helps prevent glass damage. With its combination of customizable size, strong airflow, and optional features, the Air Float Table is a smart investment for any glass fabrication shop looking to boost output and improve workflow.