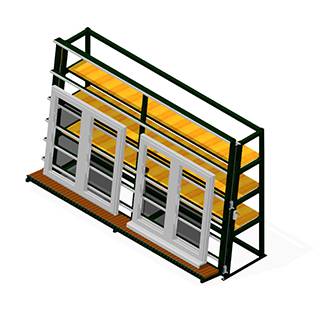

The Glazing and Squaring Rack is a versatile tool for assembling, glazing, and inspecting windows and doors. It secures and squares frames for precise, efficient production. Built for fenestration manufacturers, it integrates seamlessly into production lines to improve speed, accuracy, and workflow efficiency.

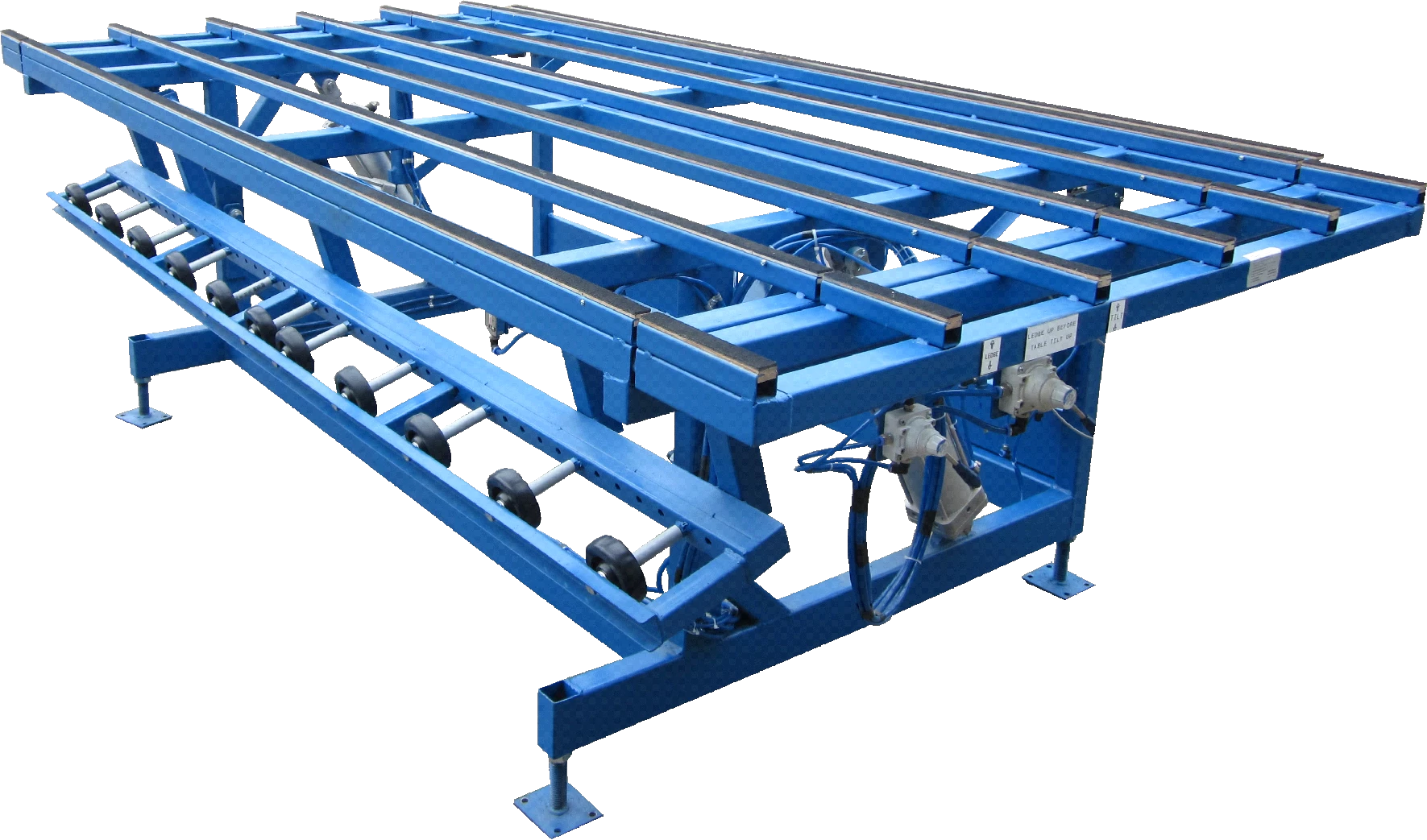

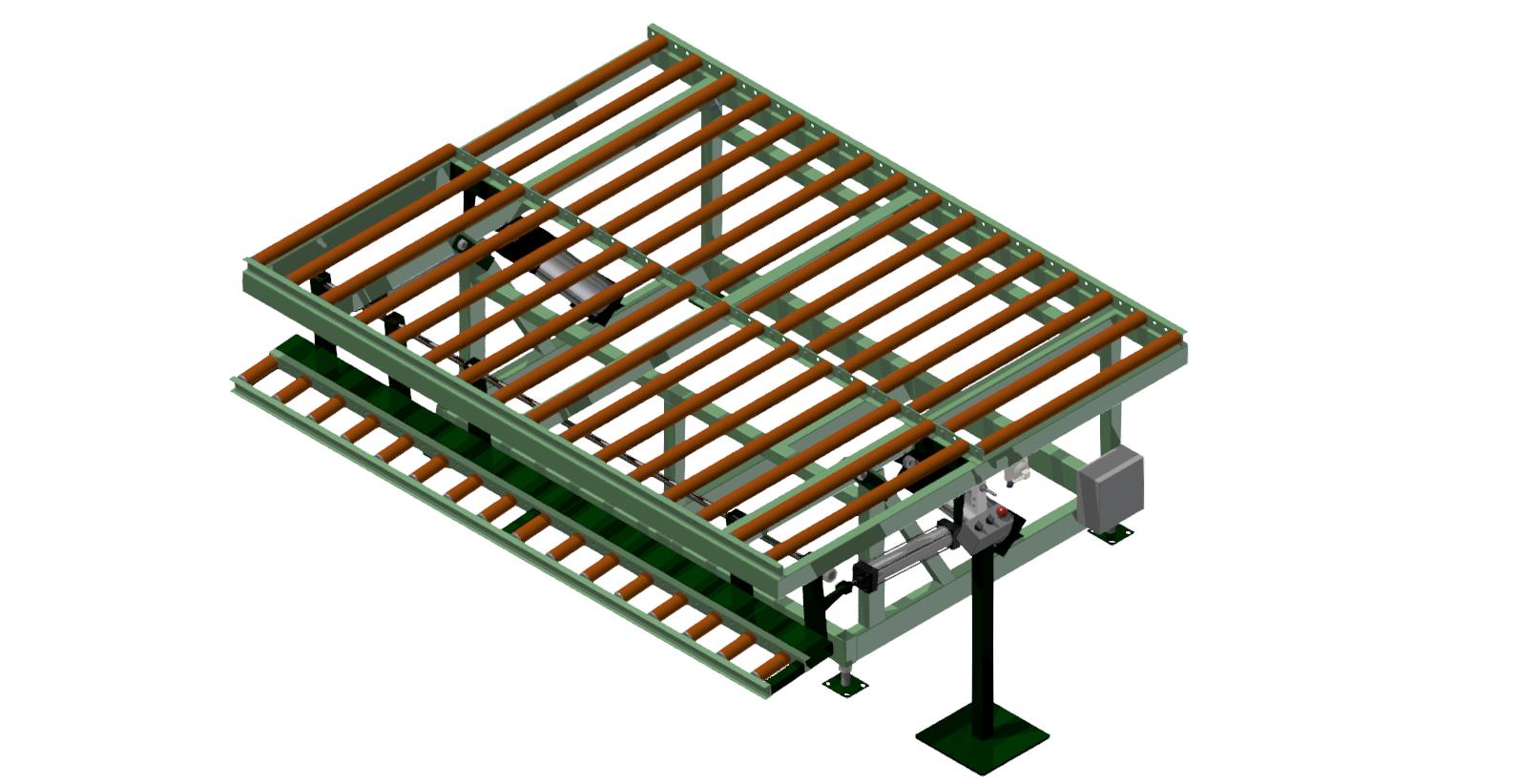

This rack features customizable dimensions and weight capacities, making it adaptable to many window, door, and patio door sizes. Its pneumatic lift system raises frames up to 26 inches with smooth, controlled motion. Upgrade options include hydraulic lifts or higher pneumatic strokes for more demanding production requirements.

Pass-through gates on both sides simplify loading and unloading, reducing downtime and improving operator efficiency. To support smooth operation, the rack includes linear bearings on the main shaft, ensuring long-lasting durability and reliability.

The squaring clamp system features one fixed and one movable side, securing frames with consistent accuracy. This design guarantees proper alignment during glazing and inspection, reducing errors and ensuring higher-quality results.

The ledge design uses durable steel rollers with polyurethane tubing for safe, smooth product handling. Manufacturers can also choose a solid ledge or donut rollers for nailfin applications. These customizable features ensure the rack adapts to varied production environments.

Optional features enhance functionality further. A top clamp press provides additional frame security during assembly, while safety lips prevent tipping to protect workers and products. These upgrades make the rack flexible enough to fit both small workshops and large-scale manufacturing facilities.

The Glazing and Squaring Rack offers unmatched reliability, adaptability, and precision. It helps manufacturers streamline processes, boost productivity, and deliver consistent quality in window and door fabrication. Designed for performance and safety, it represents a valuable long-term investment for any fenestration operation.