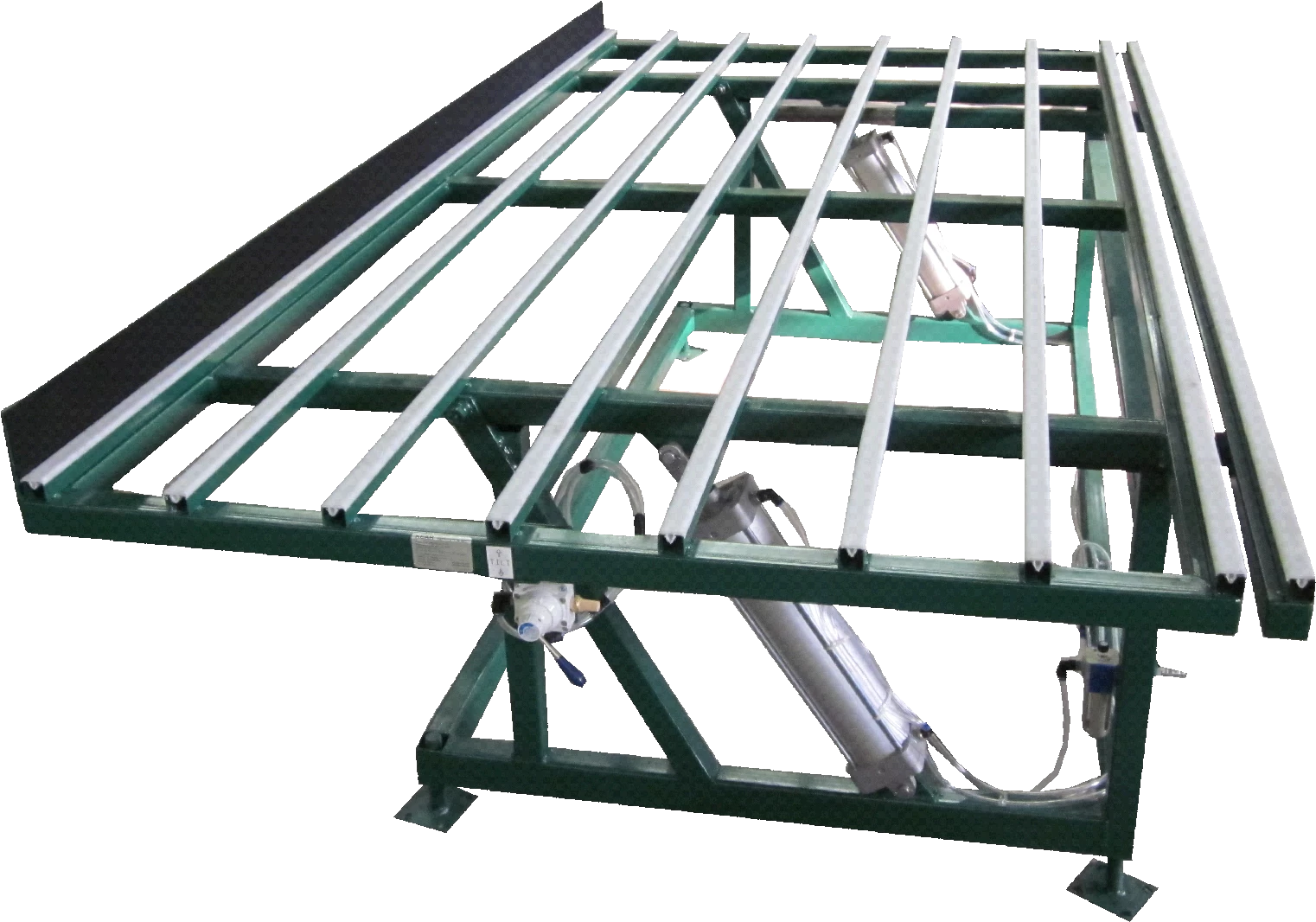

The Glazing and Squaring Rack is a high-performance tool for optimizing window and door assembly. Built for fenestration manufacturers, it simplifies assembly and inspection tasks while improving workflow efficiency.

This versatile rack features customizable dimensions and weight capacities. It handles windows, doors, and patio doors of many different sizes. The standard pneumatic lift raises frames up to 26 inches with precision stops at any height. For additional flexibility, optional hydraulic or extended pneumatic lifts adapt to demanding production needs.

The rack ensures accurate alignment with its squaring clamp system. One side remains fixed, while the other side adjusts to secure frames. This creates precise squaring during assembly, ensuring consistent quality. A pass-through design allows quick loading and unloading, reducing downtime and keeping production lines running smoothly.

The roller ledge system improves handling. Steel rollers come standard, but polyurethane covers can be added for safer, smoother operation. Standard backing consists of durable gap tubing with extruded plastic. Optional brush or rubber extrusions give additional cushioning, protecting delicate surfaces from scratches or damage.

Ergonomics and safety also define the Glazing and Squaring Rack. An optional tilt function rotates up to 90 degrees, providing workers easier access during assembly and inspections. Optional safety lips prevent products from tipping, reducing risks and enhancing workplace safety.

Manufacturers benefit from reliability, precision, and efficiency. The rack reduces manual strain, increases speed, and ensures consistent assembly results. It also supports diverse production setups, making it adaptable for small shops or large facilities.

The Glazing and Squaring Rack represents a smart investment for manufacturers seeking to boost productivity, improve quality, and streamline window and door fabrication. Engineered with durability and customization in mind, it delivers long-term performance in every production environment.