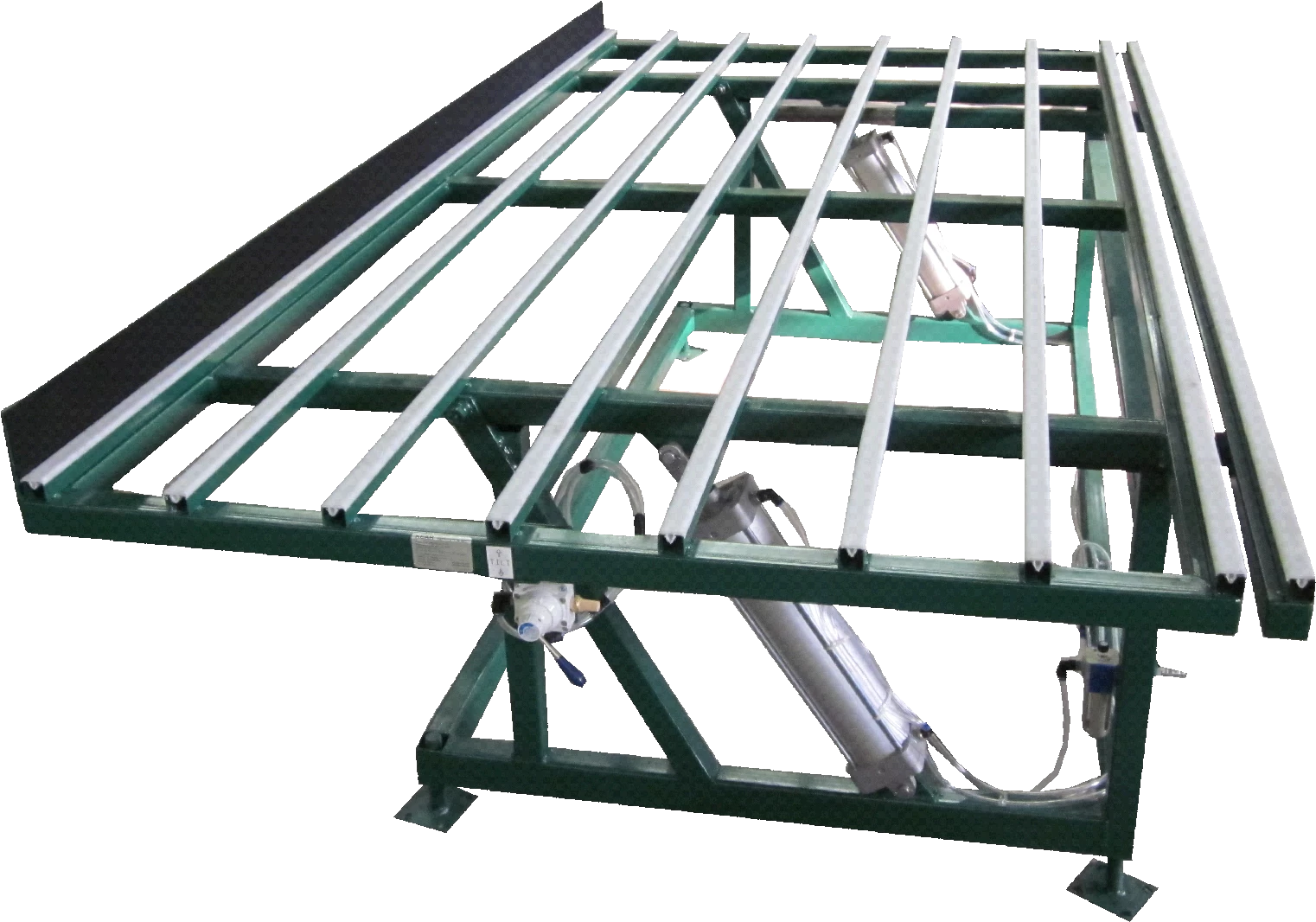

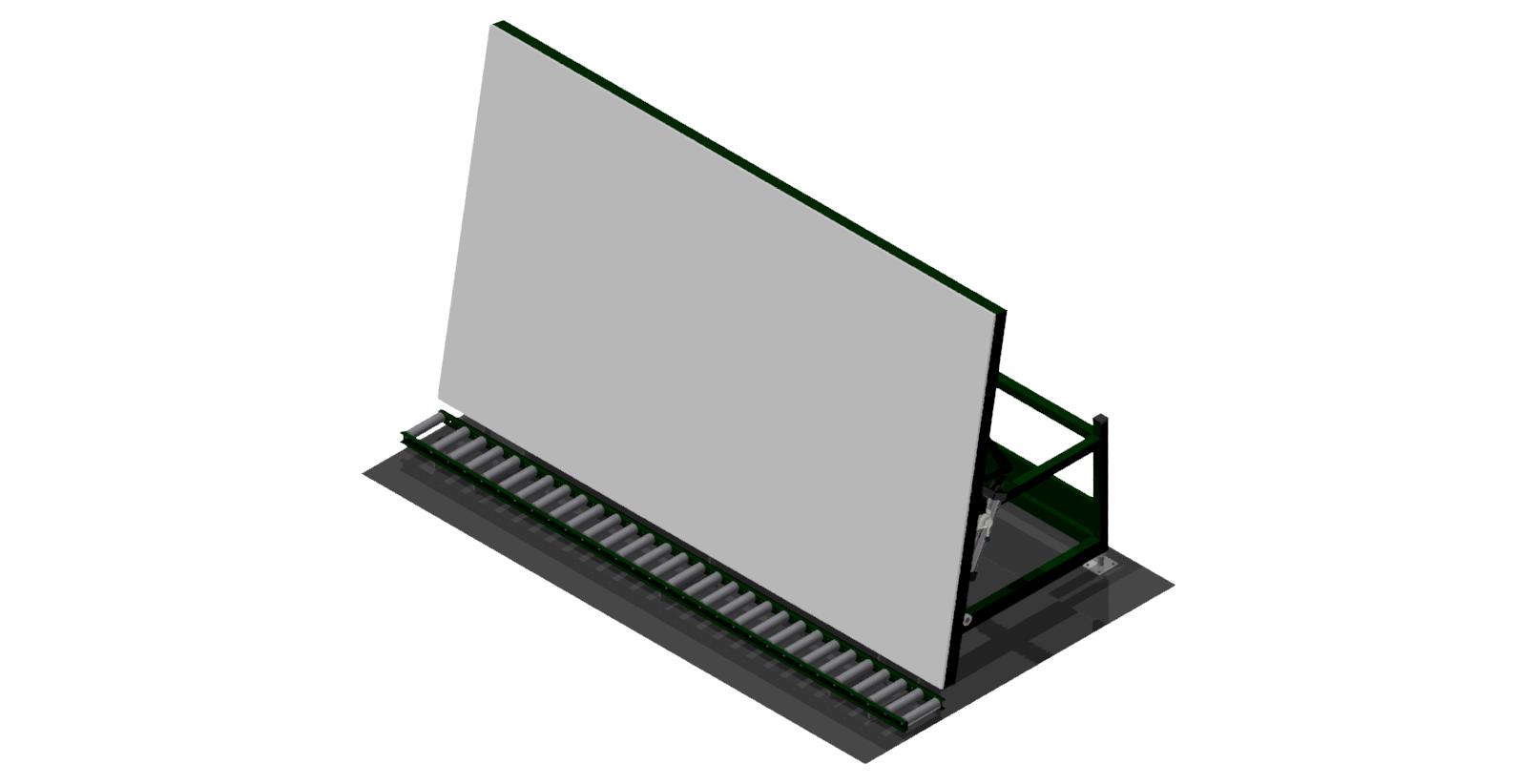

The Screen Assembly Table is a versatile and high-performance solution designed to streamline screen assembly while significantly enhancing ergonomics to benefit the health and comfort of operators. Built with customizable dimensions, it accommodates screens up to 4′ x 8′ or 5′ x 10′ as standard, with the option to customize sizes for specific production needs. The table’s precision frame alignment system, featuring round dishes, ensures that frames remain straight and stable during the assembly process, minimizing strain and reducing repetitive movements for operators. This thoughtful design not only improves assembly accuracy but also promotes a healthier and more comfortable workspace, preventing fatigue and strain.

To further enhance ergonomics and efficiency, the Screen Assembly Table includes a pneumatically powered arm that effortlessly pushes and rolls the splice into the screen. The arm’s precision bearings ensure smooth and accurate turning, allowing operators to perform tasks seamlessly and with less physical effort. The standard design features three splice roll holders, with the flexibility to add more as needed, reducing the need for frequent adjustments and further simplifying the assembly process. By minimizing manual handling and repetitive tasks, this table helps protect the health of operators while boosting productivity and precision. With its focus on ergonomics, efficiency, and accuracy, the Screen Assembly Table is an ideal choice for manufacturers committed to maintaining a safe and comfortable working environment.